Cold heading tes tsho Manufacturer

Cov yam ntxwv ntawm txias taub hau forging txheej txheem

1. Lub taub hau txias yog ua tiav ntawm chav tsev kub.Lub taub hau txias tuaj yeem txhim kho cov khoom siv ntawm cov hlau.

2. Txias taub hau forging txheej txheem tuaj yeem nce cov khoom paj paj.Nws yog txoj kev siv tshuab siab raws li cov yas deformation, uas tuaj yeem paub txiav tsawg dua lossis tsis txiav.Kev siv cov khoom siv dav dav yog nyob rau hauv 85% saum toj no, siab tshaj tuaj yeem ncav cuag 99% saum toj no.

3. tuaj yeem txhim kho kev tsim khoom.Cov khoom hlau deformation lub sij hawm thiab cov txheej txheem yog luv luv, tshwj xeeb tshaj yog nyob rau hauv ntau lub chaw nres tsheb sib sau tshuab ua qhov chaw, tuaj yeem txhim kho cov khoom tsim tau zoo.

4. Txias forging tshuab tuaj yeem txhim kho qhov roughness ntawm cov khoom thiab ua kom cov khoom raug.

Kev xav tau ntawm cov txheej txheem txias taub hau forging ntawm cov khoom siv raw

1. Cov tshuaj muaj pes tsawg leeg thiab cov khoom siv kho tshuab ntawm cov khoom siv raw yuav tsum ua raws li cov qauv tsim nyog.

2. Raw cov ntaub ntawv yuav tsum tau spheroidized annealing kev kho mob, metallographic qauv ntawm cov khoom yog spherical pearlite qib 4-6.

3. Lub hardness ntawm raw cov ntaub ntawv, thiaj li yuav txo tau lub cracking nyiam ntawm cov ntaub ntawv ntau li ntau tau thiab txhim kho lub neej kev pab cuam ntawm pwm, txias-draw cov ntaub ntawv yuav tsum muaj tsawg hardness li sai tau los txhim kho plasticity.Lub hardness ntawm raw cov ntaub ntawv feem ntau yuav tsum tau nyob rau hauv HB110 ~ 170 (HRB62-88).

4. Qhov tseeb ntawm cov khoom siv kos duab txias yuav tsum tau txiav txim siab raws li cov kev cai tshwj xeeb ntawm cov khoom thiab cov txheej txheem.Feem ntau hais lus, qhov tseeb ntawm

5. Qhov zoo ntawm cov khoom siv kos duab txias yuav tsum tau ua kom cov zaj duab xis lubricating yog npub, thiab qhov chaw yuav tsum tsis muaj khawb, folds, tawg, plaub hau, xeb, oxide daim tawv nqaij thiab pits pitting thiab lwm yam tsis xws luag.

6. Tag nrho cov thickness ntawm decarburization txheej nyob rau hauv cov kev taw qhia ntawm lub txias yog nqus cov ntaub ntawv lub vojvoog yuav tsum tsis txhob ntau tshaj 1-1.5% ntawm txoj kab uas hla ntawm raw cov ntaub ntawv (qhov xwm txheej tshwj xeeb yog nyob ntawm qhov yuav tsum tau ntawm txhua lub chaw tsim khoom).

7. Txhawm rau kom paub meej qhov zoo ntawm kev sib sau txias, cov khoom siv kos duab txias yuav tsum muaj qhov tawv tawv thiab lub xeev mos.8. Txias-sab saum toj forging xeem yuav tsum tau nqa tawm rau cov ntaub ntawv txias-daws, thiab rhiab heev ntawm cov ntaub ntawv rau txias-ua hauj lwm hardening yuav tsum tsawg li sai tau, thiaj li yuav txo tau qhov nce ntawm deformation kuj vim txias-ua hauj lwm hardening thaum lub sij hawm. deformation.

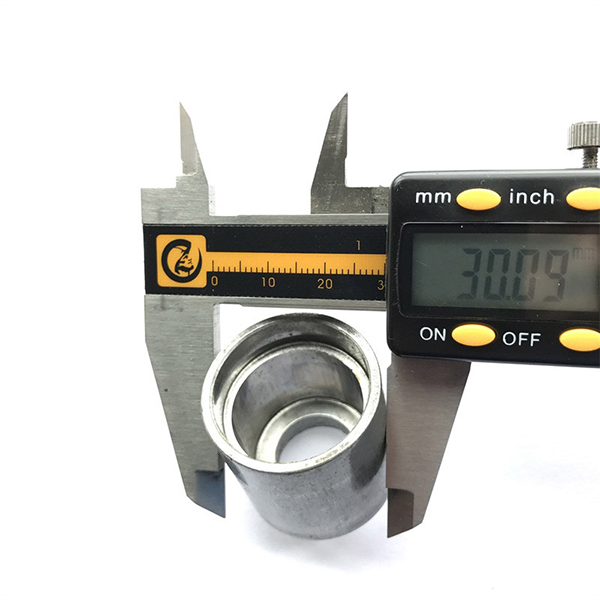

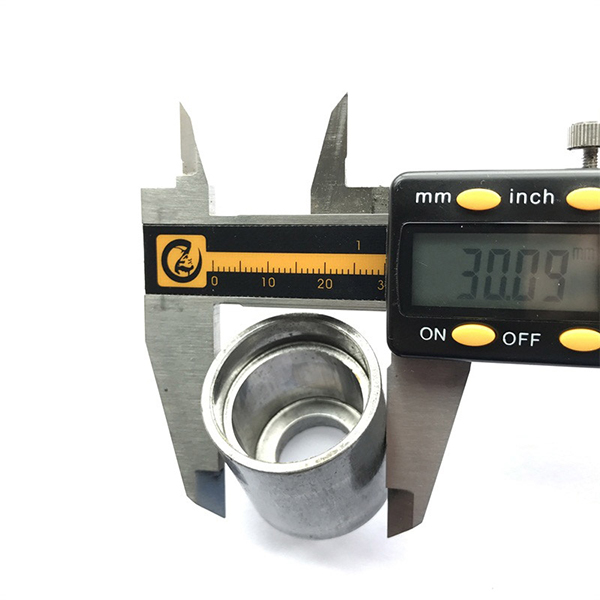

Khoom Qhia